AI-Powered Object Recognition for MRI Stud Detection

Helping Siemens Healthineers replace manual inspections with real-time AI accuracy—cutting delays, boosting consistency, and simplifying servicing across global teams

Client:

Date:

Service:

Clutch Rating:

Overview

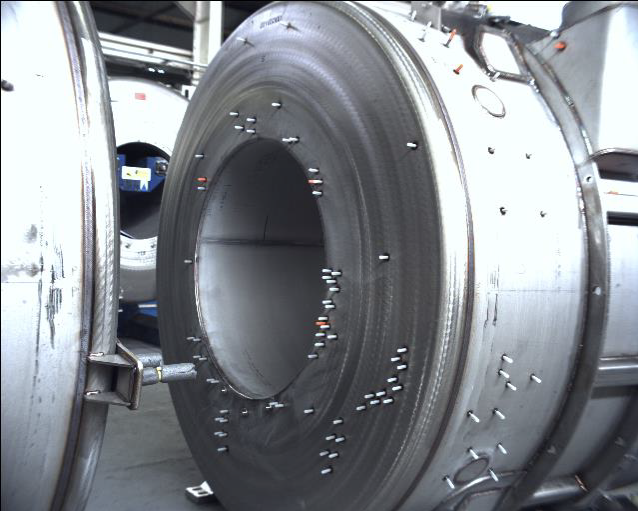

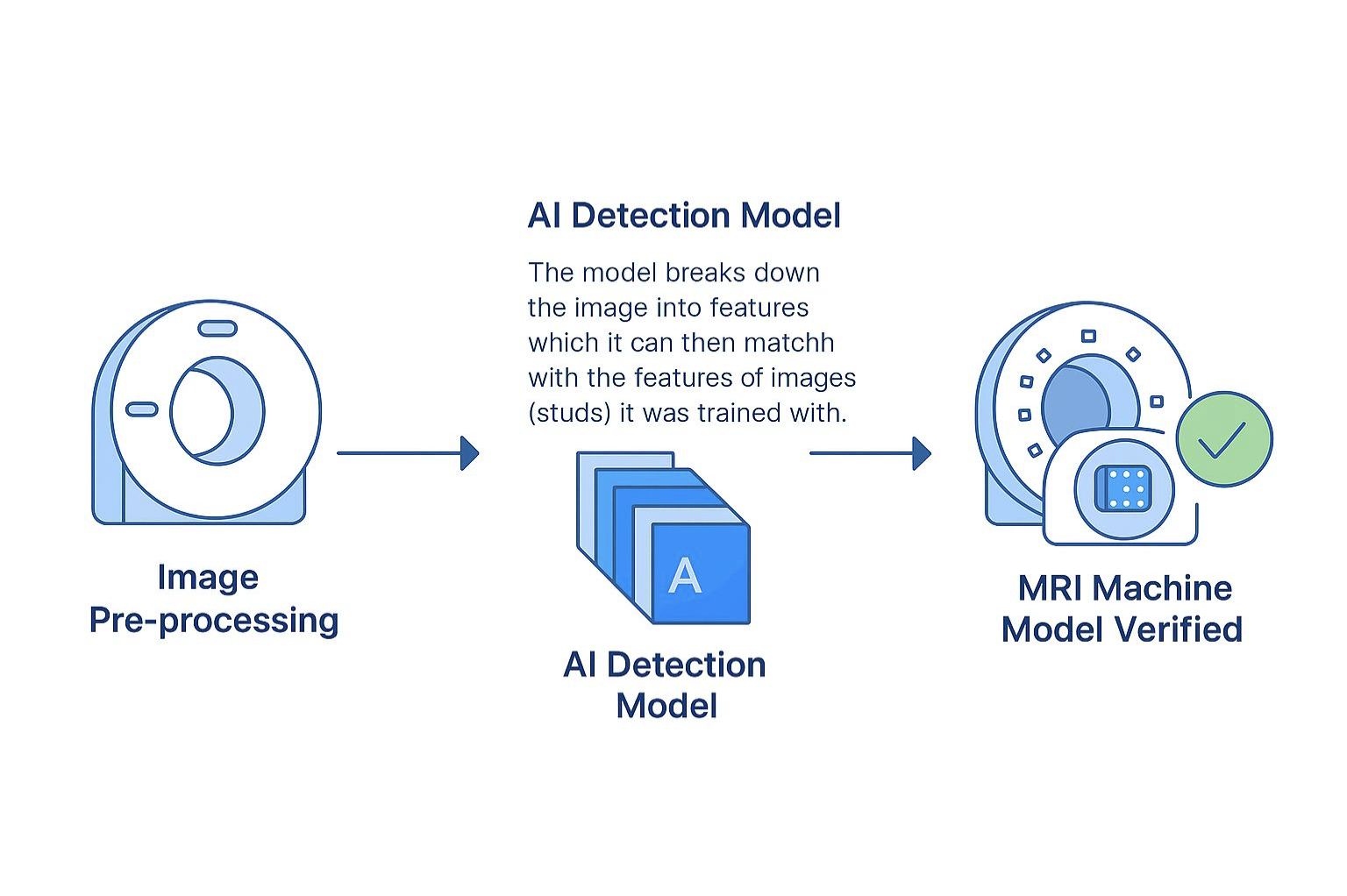

Siemens Healthineers set out to improve how MRI machines are identified and validated during routine field inspections. Traditionally, this meant technicians manually counting calibration studs—an error-prone and time-consuming process that varied across machine models and conditions.

To solve this, QuantumXL was brought in to build an AI-powered object recognition system that could automate stud detection from standard images. The goal was clear: speed up inspections, reduce inconsistencies, and enable real-time results—without adding complexity in the field. What followed was a practical application of computer vision that made a measurable impact on everyday medical equipment servicing.

The Challenge:

Manual stud counting during inspections was time-consuming and error-prone

Model variation across MRI machines made identification more complex

Real-world conditions affected image clarity and detection accuracy

A scalable, cloud-connected workflow was needed for global technician access

Siemens required a solution that was fast, consistent, and easy to use in the field

The Solution:

Model Architecture: Leveraged AlexNet, a lightweight yet powerful CNN architecture, selected for its strong performance on high-resolution spatial data

Training Process: Trained the model using standalone stud images, applying data augmentation techniques to ensure robustness across variable field conditions

Automatic Machine Identification: Extended the solution to recognise specific MRI machine models by interpreting stud configurations, reducing the need for manual input

Cloud Integration: Deployed the system via a cloud-based API to enable fast, scalable, and reliable access for technicians across locations

What Changed with AI-Driven MRI Stud Detection

By combining AI object recognition with cloud integration, Siemens Healthineers was able to automate a manual and error-prone inspection process. What once required careful visual verification in the field could now be completed faster and with greater consistency.

The solution allowed technicians to upload images and receive accurate, real-time results—regardless of model variation or environmental factors. It streamlined MRI machine validation and laid a foundation for wider AI-driven efficiencies in medical device servicing.

How AI Enhanced the System

Object detection with CNNs recognised studs with high accuracy

Probability scoring assigned confidence levels to each detection

Data augmentation improved resilience across lighting and image variations

Cloud-based processing enabled real-time accessibility for technicians

The Results

Automated detection and counting of studs across multiple MRI machine models

Significantly reduced inspection time and human error in the field

Scalable workflow integrated into Siemens Healthineers’ servicing process

Foundation for further AI-led automation in equipment validation

Key Takeaway

This project highlighted how AI can solve focused, operational challenges in the medical technology space. Automating MRI stud detection allowed Siemens Healthineers to move past slow, manual inspections and introduce a more scalable, consistent process across their servicing workflow.

QuantumXL developed a computer vision system that delivered results with speed, precision, and minimal field complexity—ready for real-world deployment.

They really listened to the brief and delivered above and beyond. The solution they created was a beautiful, easy to use app, which demonstrated their professionalism and quick understanding of our needs. They felt like an extended part of the internal team with their friendliness, coupled with their quick and thorough communication process.

Jamie Dallman

Let’s Build What’s Next

Bring your ideas to life with explainable, scalable AI—built for real-world impact.